Are you looking for a reliable partner for high-quality conveyor technology components such as forged scraper chains, redler chains, sliding rails, or sprockets?

Do you need custom-fit solutions precisely tailored to your system and requirements? Then KS-Tech is the right choice for you! We manufacture with precision and flexibility – with a focus on quality, durability, and functionality. Made in Austria.

Since 2022, we have been manufacturing at our modern facility in Erl, equipped with an entirely new fleet of machines. This allows us to precisely process a wide range of materials such as steel, stainless steel, and wear-resistant special alloys – ideal for durable and high-performance conveyor components.

Drop forged scraper chains – Redler Chains

High-quality materials and precision manufacturing – single or double-strand drop forged scraper chains.

Durable Drop Forged Scraper Chains (Redler Chains) for Demanding Industrial and Power Plant Applications

Our drop forged scraper chains – also known as Redler chains – are available in single or double-strand designs and have been successfully used across various industries for decades. Typical applications include thermal power plants, biomass plants, waste incineration facilities, particleboard production, and many other areas involving bulk material handling. Since 1988, our company founder has focused on the development and optimization of high-performance conveying systems, providing our customers today with in-depth expertise and decades of practical experience.

For the production of our high-performance chains, we rely on 18MnCrB5 alloy steel, which—thanks to its higher boron content compared to 20MnCr5—offers increased toughness and wear resistance, particularly at heavily stressed fork links. The result: extended service life, high operational reliability, and minimized maintenance costs.

Naturally, we also manufacture custom scraper chains tailored to your technical requirements, operating conditions, and material specifications.

Special designs made from stainless steel are also available – ideal for challenging environments where aggressive media or high temperatures demand exceptional material properties.

Rely on proven quality, durable materials, and our decades of experience in drop forged scraper chains.

Forged Link Chains

Redler Chains

Tailor-made solutions for the highest demands – with decades of experience and uncompromising quality, we set the standard.

Slide Rails – Manganese wear Strips

Extremely wear-resistant for your conveyor systems

Slide Rails and Manganese Wear Strips – Maximum Wear Resistance with High Impact Toughness

Our slide rails and manganese wear strips offer outstanding wear resistance combined with high impact toughness – making them ideal for use in conveyor systems, trough conveyors, elevators, construction material and recycling plants, as well as bulk material handling.

We stock standard manganese strips with a base length of 3,050 mm for immediate delivery. Depending on your application, our wear rails are available:

With or without profile

In material grade X120Mn12 (1.3401) – also known as Hadfield steel

The initial hardness of the rails is approximately 220–250 HB. Due to the work-hardening effect under stress, the surface hardness increases during operation to up to 600 HB, making them highly resistant to abrasion and impact loading.

KS manganese strips are the top choice for customers who demand long service life, minimal maintenance, and maximum durability in heavily stressed systems.

We are also happy to provide custom lengths, hole patterns, or precision machining upon request.

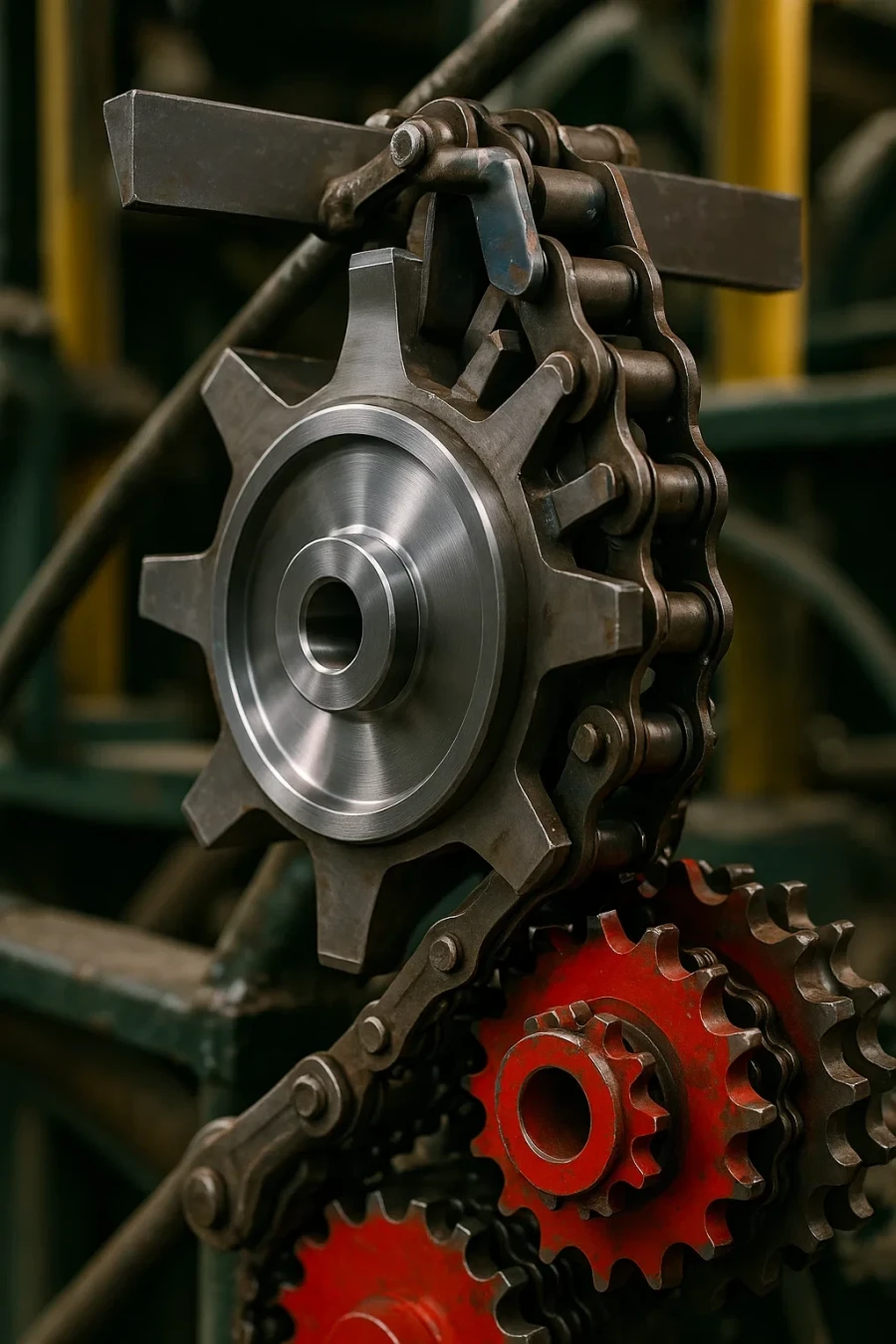

Sprockets and Return Pulleys

precisely manufactured for maximum service life and optimal power transmission

Sprockets and Return Pulleys – Precisely Engineered for Reliable Performance

We offer a wide range of sprockets and return pulleys in various designs, specifically tailored to your drive and conveyor systems. Our components ensure reliable power transmission, high dimensional accuracy, and long service life – even under demanding operating conditions.

Our product range includes:

One-piece drive sprockets

Multi-part drive sprockets (segment design)

Drive sprocket stars

Return pulleys for chain guidance and directional changes

Custom-made special designs

All products are available in various steel grades – such as C45, 16MnCr5, high-wear-resistant tempered steels, or corrosion-resistant stainless steels – precisely selected to match the application, load profile, and environmental conditions.

Our precision-manufactured components are used worldwide in conveyor systems, recycling technology, power plants, biomass facilities, bulk material handling, and many other industrial applications.

We also implement custom modifications such as special bores, keyways, heat treatment, or surface finishing – quickly and reliably, according to your specifications.

Steel grade / quality

Highest standards from EU production for long-lasting conveyor technology

Premium EU Steel Grades for Durable Conveyor Chains

For our conveyor chains, we exclusively use high-quality steel from EU production, meeting the highest performance standards and delivering reliability in every respect. We offer a broad selection of steel grades to suit the specific demands of your applications:

Standard grades for everyday use

Stainless steel grades for corrosion-resistant solutions

Special alloys for particularly demanding conditions

Thanks to our trusted EU-based suppliers, we ensure consistently high material quality and a secure, traceable production process. Of course, special steel grades are also available upon request – precisely tailored to your individual requirements and operating conditions.

Our conveyor chains made from EU-quality steel provide maximum wear resistance, durability, and operational safety – even under extreme loads and harsh environments.

Machinery fleet

Precision and performance through state-of-the-art machinery

Here you’ll find impressions of our machinery fleet, which is continuously being expanded with additional equipment. If you have any questions about our machines or processing capabilities, please don’t hesitate to contact us.

We look forward to supporting you with your project.

About us

KS Kneissl & Senn Technologie GmbH

Your One-Stop Shop for lubricants, seals, foundry supplies, insulation solutions, conveyor chains, and compensators.

Our product portfolio includes:

Conveyor chains

Sealing solutions

Chesterton products

Foundry supplies

Refractory materials

Compensators

Slide bearings

Logistics services

Metal fabrication

Key figures of the group

- The SENN Group – Your Industrial Solutions from a Single SourceThe SENN Group is the umbrella brand of Senn Beteiligungs GmbH, comprising several companies operating in the industrial supply sector. Founded in 2001, the group enables us to offer you everything from a single source – from individual components to complete system solutions.With just one click, you can learn more about our products and business areas.

- Group revenue: €34 million

- Employees: 100

- Locations: Austria and Germany

- Founded: 2001

DOWNLOADS

Product Overview

The SENN Group combines the strengths of multiple specialized companies to offer a broad portfolio of high-quality products and services for industrial applications:

Conveyor Chains

Precision-engineered chains for bulk material handling, power plants, and heavy-duty conveying systems.Sealing Technology

Standard and custom seals for reliable operation in mechanical, hydraulic, and process systems.Chesterton Products

Comprehensive range of mechanical seals, packing, specialty lubricants, and protective coatings.Foundry Supplies

Consumables and equipment for casting, molding, and core-making processes.Refractory Materials

High-performance insulation and refractory products for extreme temperature environments.Compensators

Fabric and metal expansion joints designed to absorb thermal movement, vibration, and pressure fluctuations.Slide Bearings

Maintenance-free and high-load-capacity plain bearings for industrial and structural applications.Lubricants

High-grade industrial lubricants tailored for specific mechanical and environmental requirements.Metal Fabrication

Custom CNC machining, welding, and component manufacturing in various steel grades.Logistics Services

Professional warehousing, distribution, and supply chain management for industrial goods.

Through these combined competencies, the SENN Group serves as a full-service provider for industrial supply, offering both standardized and custom solutions from a single source.

ISO9001:2015

As a company, quality is our top priority – which is why we have been ISO 9001 certified since 2008.

Job highlight

Machining Technician – Turner / Miller

We are an innovative company in the field of metal processing and are currently looking for a dedicated and qualified CNC Turning and Milling Technician to join our team as soon as possible. In this role, you will be a key figure in our production process.